Wheel balancing is not forgiving. Unlike alignment, where small errors can sometimes be corrected, wheel balancing accuracy depends entirely on rotational symmetry, shaft precision, and sensor stability.

OEM compatible wheel balancer spare parts are designed to preserve these exact parameters—without forcing workshops to overpay for original spares.

If the spare part is even slightly off, the machine will show repeat imbalance, vibrations won’t disappear, and customers will lose trust. Simple as that.

How OEM Compatibility Impacts Wheel Balancing Accuracy

OEM compatible balancer spares are engineered to replicate original components dimension by dimension, not “approximately.”

A properly manufactured OEM compatible balancer spare ensures:

- Perfect shaft concentricity – critical for true rotation

- Stable rotation at high RPM – no wobble, no oscillation

- Accurate imbalance detection – sensors read what’s actually wrong, not what the machine introduces

Even a fraction of a millimeter error in cones, shafts, or nuts can cause:

- Repeat balancing complaints

- Inconsistent readings

- Customer arguments and rework

That’s why compatibility is not optional—it’s mandatory.

Common Wheel Balancer Spare Parts That Affect Accuracy

These parts take the most mechanical load and directly influence results:

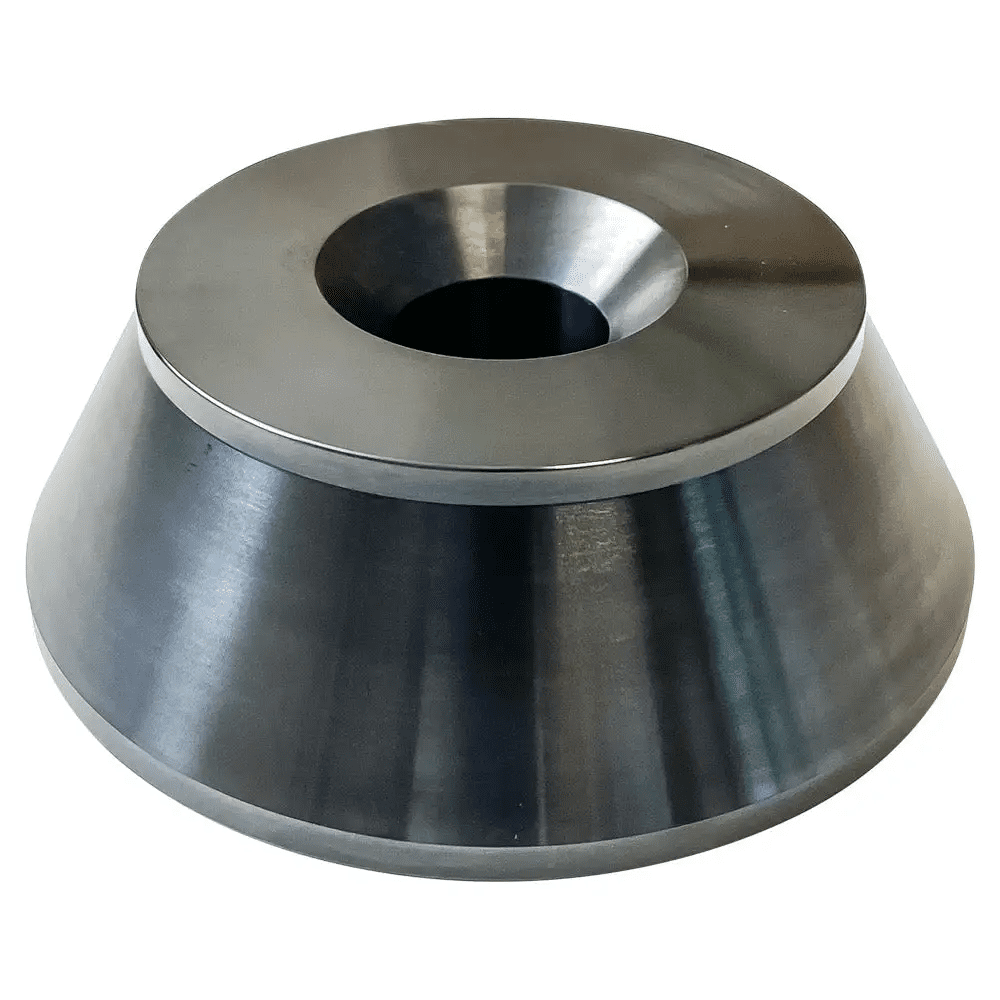

⚙️ Wheel Balancing Cones

Cones center the wheel on the shaft. Poor-quality cones cause eccentric mounting, leading to false imbalance readings.

🔩 Quick-Release Nuts

These lock the wheel in position. Inconsistent clamping pressure results in micro-movement during rotation.

🛠 Wheel Balancer Weight Pliers

Incorrect pliers damage weights and rims, leading to improper weight placement and repeat vibrations.

Each of these parts must maintain tight tolerances and material strength—there is zero room for compromise.

Benefits of OEM Compatible Wheel Balancer Spare Parts

When manufactured correctly, OEM compatible spares deliver real operational advantages, not just cost savings.

✅ Improved Balancing Repeatability

The same wheel gives the same reading—every time. No guesswork, no rechecks.

✅ Reduced Bearing Wear

True rotation reduces side loads on bearings, significantly extending bearing life.

✅ Lower Vibration Levels

Balanced internal mechanics prevent machine-generated vibration that contaminates readings.

✅ Extended Machine Service Life

Less stress on shafts, sensors, and motors means fewer breakdowns and lower maintenance frequency.

Ideal for High-Volume Workshops

Workshops balancing dozens of wheels daily cannot afford:

- Frequent recalibration

- Premature bearing failure

- Inconsistent results

OEM compatible balancer spares are built to handle continuous operation while offering a lower total cost of ownership compared to original parts.

This is why serious workshops quietly switch—even if they don’t say it publicly.

Sarveshwari Engineers Manufacturing Standards

Sarveshwari Engineers follows strict production and testing protocols to ensure every spare performs like the original:

- CNC machining for dimensional accuracy

- Dynamic testing under rotational load

- Runout tolerance inspection

- Consistency checks across batches

The result: stable balancing, longer machine life, and predictable performance—not marketing promises.

Final Reality Check

If your wheel balancer:

- Gives different readings for the same wheel

- Vibrates excessively

- Eats bearings frequently

The issue is not always the machine—it’s usually poor-quality spares.

OEM compatible wheel balancer spare parts fix the problem when they’re engineered properly.

📩 Call to Action

Contact Sarveshwari Engineers for OEM-compatible wheel balancer spare parts that protect accuracy, reduce wear, and keep your machines running longer—without OEM pricing pressure.