Wheel chocks are a crucial piece of equipment for maintaining the security of parked or being worked on cars. They stop the car from rolling or moving, preventing accidents and property damage. It might be difficult to pick the proper wheel chocks, but doing so is essential to ensuring the highest level of safety.

How do you choose the finest wheel chock for you when there are several options available? Well, “No Chock Fits All,” and your car’s safety is dependent on a number of variables. So always go by the instructions provided by the vehicle’s manufacturer and properly test any new brakes before putting them to long-term use. Here are some broad guidelines to guide you in making the correct chock decision.

Wheel Chock Design and Components

Finding the appropriate form for the car you plan to protect is the first step. While certain reinforced plastic variants of our wheel chocks are available in both lightweight and durable varieties, the bulk of them is composed entirely of natural or synthetic rubber.

1. Size and Weight Capacity

Size and weight capacity are the first and most crucial factors to take into account when selecting the best wheel chocks. The chocks must be able to sustain the weight of the car and be sized to accommodate the wheels of the vehicle. For the vehicles you will be dealing with, look for chocks that are made to their weight and dimensions. The chocks might not be able to stop the car from moving if they are too weak or too tiny.

2. Material

A variety of materials, including rubber, plastic, and metal, are used to make wheel chocks. The most popular material for wheel chocks is rubber since it has an excellent grip and is long-lasting. Another common type of chock is plastic, which is lightweight and convenient to use. Although less prevalent, metal chocks are sturdy and capable of supporting higher weights. Select the material that best meets your demands while keeping in mind the sort of vehicle you’ll be dealing with.

3. Ground

Another crucial aspect to take into account is the surface where the chocks will be installed. You’ll need chocks with high grip if the surface is smooth, like concrete or asphalt, to stop slippage. For flat surfaces, rubber chocks make sense since they offer high traction. You may require chocks with a more aggressive tread pattern if the surface is tough, such as gravel or dirt, in order to offer a stronger grip.

4. Slope

The slope of the surface where the chocks will be installed is a crucial consideration. For best stability on a sloping surface, you might require chocks that are wedge-shaped. Before working on the vehicle, look for chocks that are intended to be used on slopes and make sure they are firmly in place.

5. Shape

Another crucial aspect of the wheel chocks is their form. Some chocks are straight, while others are bent to match the curve of the wheel. In contrast to the straight form, which is better for preventing sliding, the curved shape is better at preventing rolling. Pick the form that best satisfies your requirements.

6. Amount of Wheels

When selecting wheel chocks, take the vehicle’s wheel count into account. When a vehicle has two wheels, it only needs one chock per wheel; when it has four wheels, it needs two chocks for each wheel. Make that you have enough chocks to hold the car securely.

7. Storage

Finally, think about where you’ll keep your tyre chocks. When not in use, wheel chocks can take up a lot of room, so it’s crucial to select chocks that can be conveniently stored. To minimise space, look for boxes that can be stacked or hung on a wall.

The following is a list of various unique wheel chock shapes:

Compared to standard chocks, aircraft wheel chocks are longer and include a colour-coded cable that makes manual deployment simple.

For big cargo and construction trucks up to 40 tonnes, double-sided pyramid wheel chocks are the best option. They have an excellent tread and may be equipped with handles or eyelet pins for simple construction. Additionally, Yellow Rubber Chocks are offered to improve visibility in low-light weather.

Typically, a standard Wheel Chock is needed for most vehicles, vans, and travel trailers. The following stage will be determined by the size of your tyres and the weight of your vehicle.

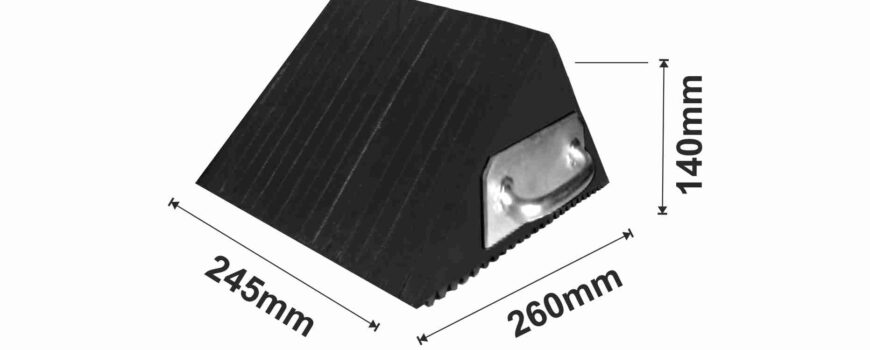

How To Measure Wheel Chocks

The height and size of the wheel chock are the most crucial considerations. It is advised that the chock’s height be at least a quarter of that of the wheel. If the car is going to be parked on an incline, much higher. Choose a size that will comfortably fit your wheel after measuring its height and breadth. Next, evaluate the vehicle’s weight and the maximum load that the wheel chock can support. Some chocks have hollow interiors to minimise their weight and cost, which also lowers the amount of weight they can support.

To sum up, selecting the appropriate wheel chocks is essential for guaranteeing the security of automobiles while being parked or serviced. When selecting the best wheel chocks for your purposes, take into account elements like size and weight capacity, material, surface, slope, form, number of wheels, and storage. You may pick the best chocks to avoid accidents and provide optimum safety by taking these things into account.