Scaling in the garage equipment industry is not limited by demand—it’s limited by supply control. OEMs and distributors who depend on off-the-shelf or third-party catalog spares eventually hit the same wall: lack of differentiation, inconsistent quality, and shrinking margins.

This is where custom manufacturing becomes a growth accelerator, not just a sourcing option.

What Custom Manufacturing Really Means (No Marketing Spin)

Custom manufacturing is not just changing a logo or color. Done properly, it allows OEMs and distributors to own the supply chain.

Custom manufacturing typically includes:

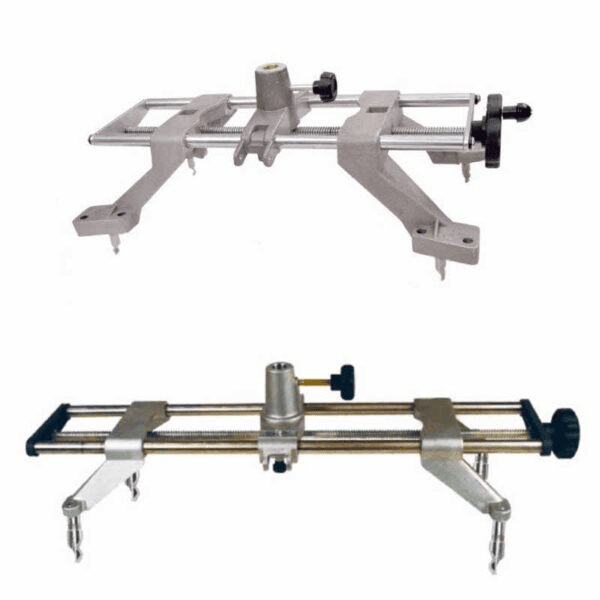

🔧 Sample-Based Development

Existing parts are reverse-engineered to match:

- Dimensions

- Functional behavior

- Load capacity

- Fitment accuracy

This ensures compatibility with existing machines without redesign risks.

📐 Drawing-Based Production

OEMs can provide technical drawings, tolerances, and material specs—allowing:

- Exact replication

- Controlled revisions

- Long-term design consistency

This is critical when scaling across regions.

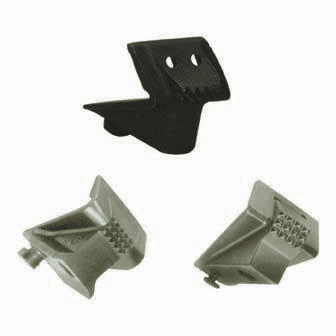

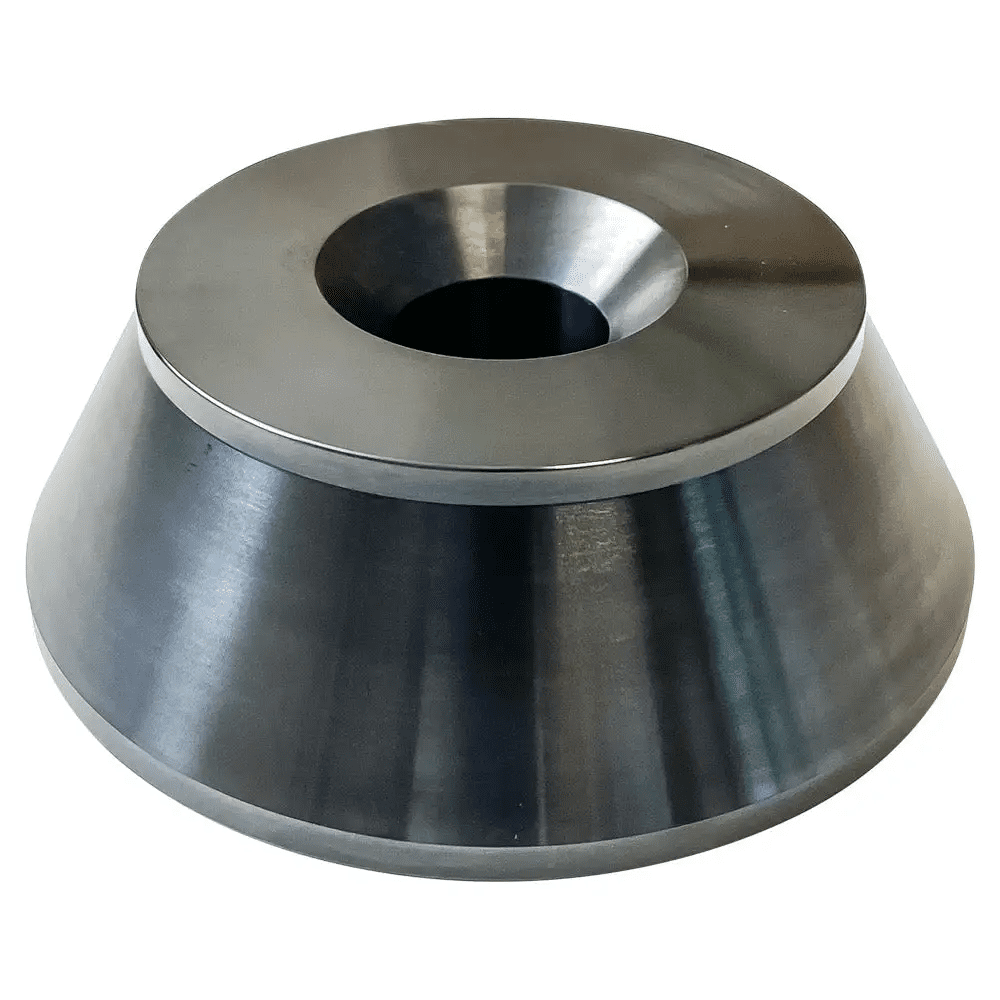

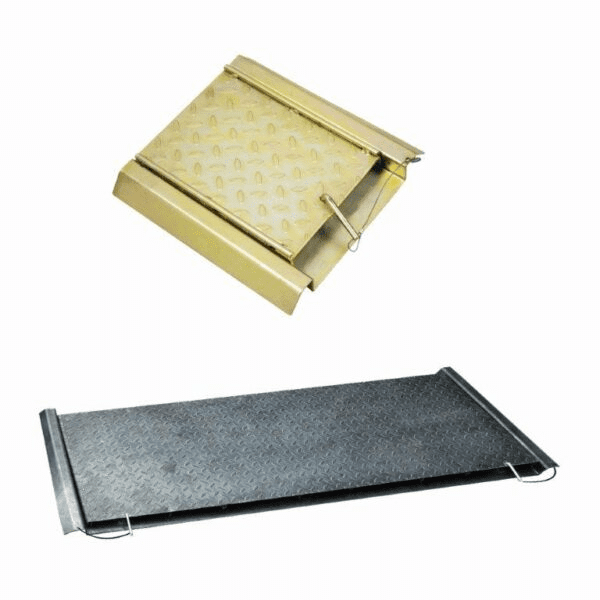

🧱 Material & Coating Customization

Different markets demand different durability standards. Custom manufacturing allows:

- Harder alloys for high-usage regions

- Corrosion-resistant coatings for coastal or humid markets

- Nylon, PU, or composite options for wheel-contact parts

You choose performance—not the factory.

📦 Branding & Packaging

Custom branding includes:

- Private labeling

- Retail-ready packaging

- Distributor-specific SKUs

This builds brand recall and prevents price-based comparison with generic parts.

Why Custom Manufacturing Helps Businesses Scale Faster

OEMs and distributors who use custom manufacturing scale faster for structural reasons, not luck.

1️⃣ Reduced Inventory Complexity

Instead of managing dozens of supplier SKUs, custom manufacturing enables:

- Standardized designs

- Predictable replenishment

- Fewer quality variations

Less chaos = faster expansion.

2️⃣ Consistent Quality Across Markets

Nothing kills growth faster than inconsistent product performance. Custom manufacturing ensures:

- Same tolerance

- Same material

- Same performance—every batch

This consistency protects brand reputation as volumes grow.

3️⃣ Competitive Pricing with Margin Control

By eliminating middle layers, OEMs and distributors gain:

- Lower per-unit cost

- Stable pricing at scale

- Higher gross margins

You grow without squeezing yourself.

Ideal for Global Expansion

When entering new regions, OEMs and distributors face:

- Local price pressure

- Different operating conditions

- Brand recognition challenges

Custom manufacturing solves this by allowing region-specific optimization without redesigning entire product lines.

That’s how global brands scale without losing control.

Sarveshwari Engineers Manufacturing Support

Sarveshwari Engineers works as a manufacturing partner, not just a supplier.

They support:

- Low-volume trial batches for market testing

- Scalable high-volume production runs

- OEM and white-label programs

- Engineering collaboration during development

This flexibility allows businesses to start small, validate fast, and scale confidently.

Straight Truth

If an OEM or distributor is still relying only on standard catalog parts, growth will always be limited by:

- Price wars

- Supply dependency

- Zero differentiation

Custom manufacturing changes the game by turning spare parts into a strategic asset, not a commodity.

Contact Sarveshwari Engineers for custom manufacturing of garage equipment spare parts designed to support faster scaling, stronger margins, and global expansion.