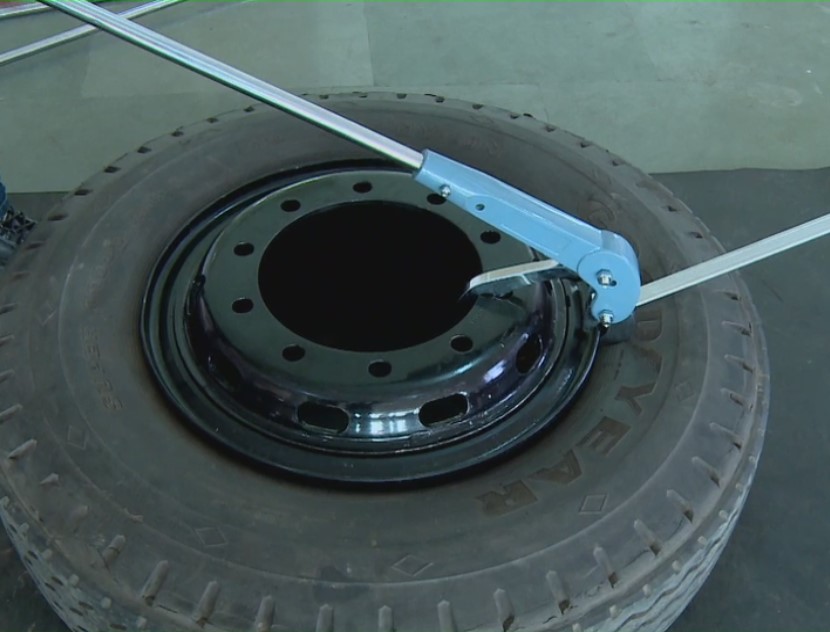

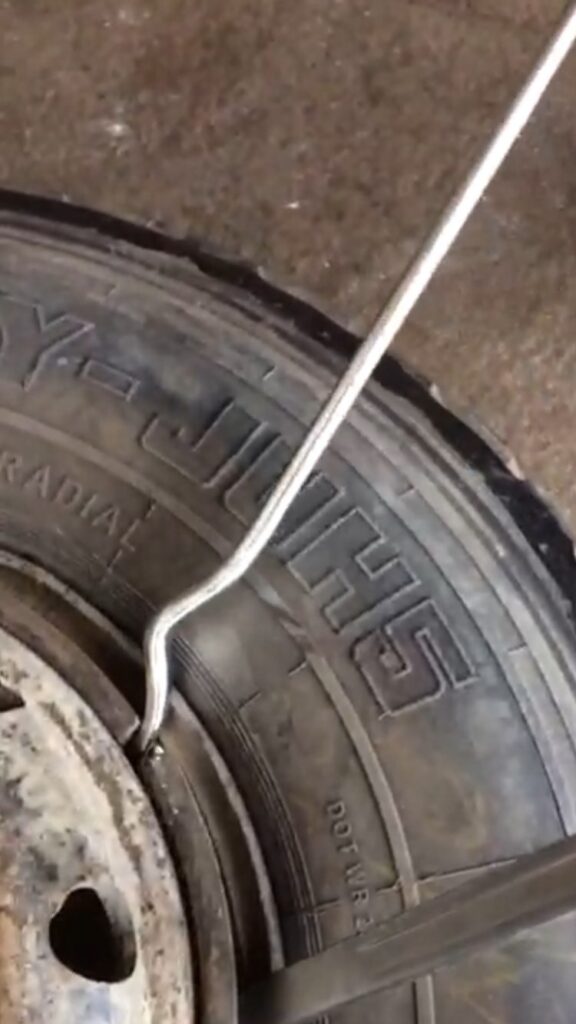

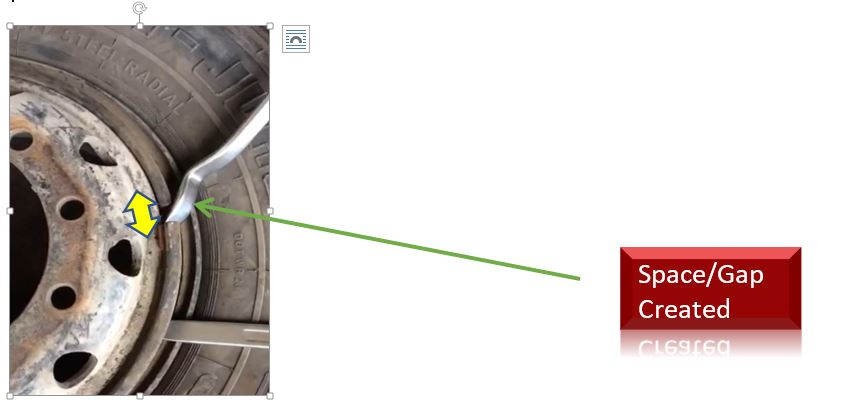

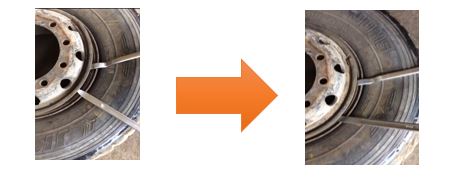

Tyre Spreaders as the name explains, spreads or pulls apart the tyre bead making it easy for the operator to look inside the tyre wall for examining any injury or repair work. Permanent Repair of the punctures is carried out by inserting tyre patches on the inside wall of the tyres. Tyre Spreader is an essential tool while carrying out inside tyre repair work. It spreads the bead or opens a tyre and holds in that position till the operator can locate an injury, &repair it.

The claws/arms on the spreaders sit inside the tyre & spread the tyre beads, and give ample space to the operator to work inside the tyre. Main purpose of using tyre spreaders is to aid the operator in making tyre repair work convenient and faster.

You can additionally also attach a bench light to the tyre to make the visibility for tyre repair more clear.

Sarv offers Tyre spreaders for Car & Light commercial Vehicle tyres in 4 Varieties. Can open a tyre from size 12” upto 24”.

4400020 is the standard tyre spreader.

44000120 is the standard tyre spreader with a plastic handle and can be easily mounted on a bench. This increases the height & makes it easier for the operator to position the tyre at the correct height.

4400320 is the manual tyre spreader which spreads the tyre with its claws. Different claw sizes show different tyre size. It can go upto a range of 330mm

4400420 Can spread the tyres from size

To order your Car Tyre Spreaders anywhere worldwide or to enquire about other SARV accessories ( Wheel Balancing Accessories , Tyre Changing accessories, Wheel Alignment Accessories , Tyre Service , Repair & Valve Tools , Tyre Levers , Puncture Repair Kits etc ) from our complete range, write to us at info@sarveshwari.com or visit our website www.sarveshwari.com